Embracing “precast innovation powered by collaboration” has positioned carbon fiber reinforced element licensor AltusGroup and producer members to sustain momentum in developing advanced commercial building enclosure solutions. “In the two decades since our founding, we’ve seen a deepened focus on energy savings, carbon footprint mitigation and on-site labor reductions, all amid an enhanced desire for aesthetic freedom and versatility,” says Executive Director John Carson. “Through our novel co-opetition model, we’ve brought a variety of innovative technologies to the marketplace to make precast an even more competitive building enclosure option—with more product development on the way.” Among the organization’s highlights the past 20 years, he cites:

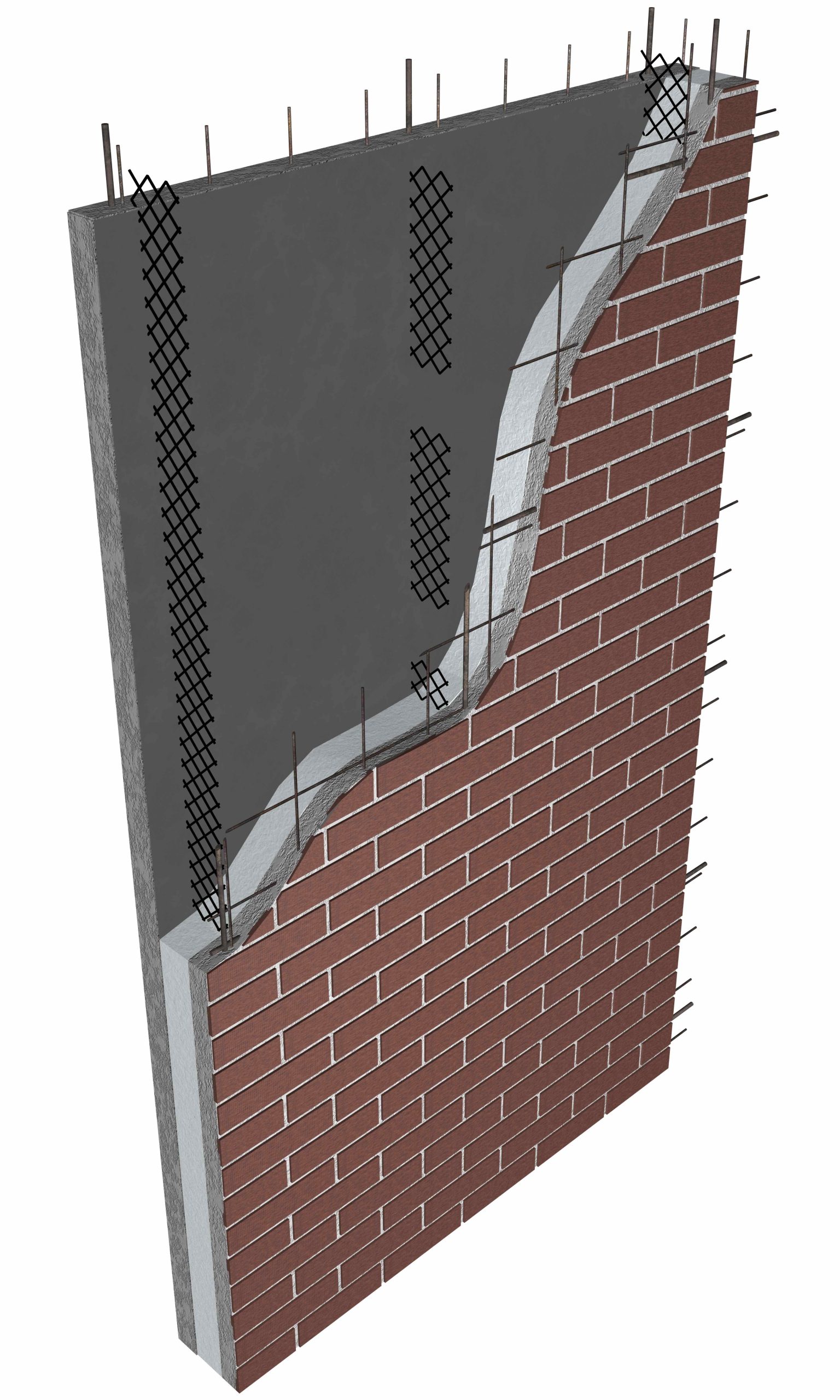

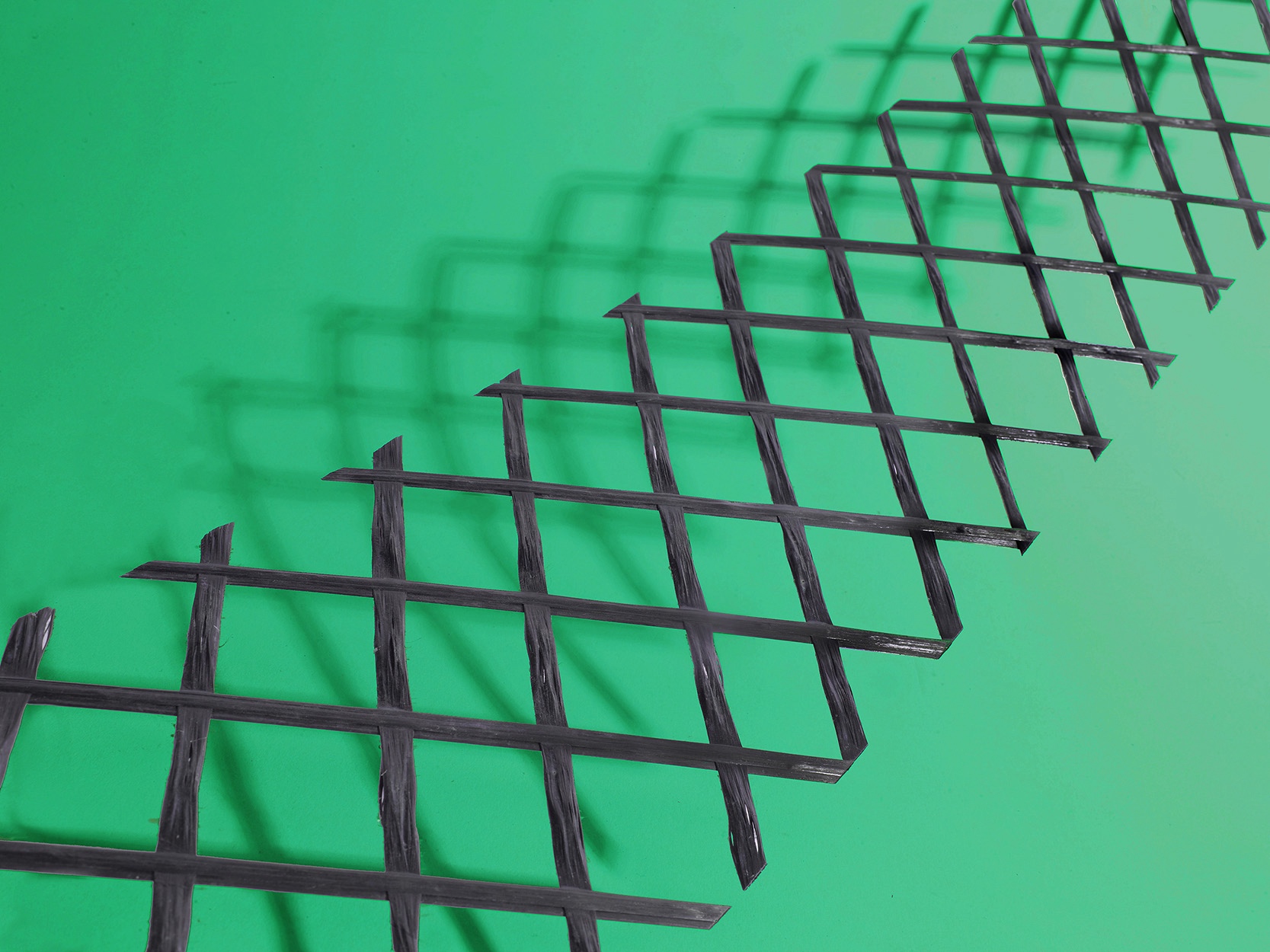

- Commercializing the world’s first insulated precast concrete wall system to use carbon fiber reinforced polymer grid as a wythe connector and for composite design action, dovetailing domestic introduction of CarbonCast as the first nationally recognized brand of precast concrete wall systems;

- A/E/C media recognition ranging from Architectural Products’ Product Innovation Award and Architect R+D Award to Buildings Top 100 Products and Architectural Record’s Product Reports;

- Growth from five charter producers to 14, a figure that had reached 19 prior to industry consolidation. An additional nine companies support the group as Innovation Partners, while an International Affiliate supplies CarbonCast product in Europe; and,

- 8,500-plus educational outreach and continuing education programs delivered in person or online since 2006.

CarbonCast technology has been successfully used on more than 2,500 projects representing 35 million square feet of wall surface since 2003. Central to AltusGroup’s success has been adherence to the co-opetition model, whereby members cooperate to develop precast advancements then compete with one another in their respective market areas. To innovate, the organization unites top engineering and production minds in precast, prestressed concrete production. Members then pool financial resources for product development, testing and marketing.

“We are nimbler than a trade organization and have a deeper pool of knowledge than any one company. We are unbridled in our thinking and actions,” Carson affirms.

He and members celebrated 20 years of accomplishment and looked to the future at the AltusGroup annual general meeting in Tampa, Fla. The late-2023 gathering saw the election of Joe Bunkers of South Dakota-based Gage Bros., as chairman, succeeding Hagen Harker of Mid-States Concrete Industries; John Arehart of Enterprise Precast, Texas as chair elect; Dave Schneider of High Concrete Group as treasurer; and, Jason Pitcole of Master Builders Solutions (Innovation Partner) as secretary. Along with officer elections, members reviewed plans for the 2024-2025 rollout of product and technology developments to speed construction, reduce jobsite labor and lower CarbonCast panels’ carbon footprint.